End the Plastic Packaging Crisis. Simplify Recycling.

The Problem:

Today, the vast majority of retail packaging, especially pouch bags, is non-recyclable. In fact, above 99% of retail pouch bags in stores end up in landfills. This widespread issue occurs because plastic packaging is often made from mixed materials, which recycling centers simply cannot process. They only accept pure streams like PET, HDPE, Glass, and Aluminum.

Our Solution:

HDPE R2Film offers a tangible solution. Join us and standardize all packaging to a single, high-quality HDPE material. This ensures every retail package is easily recyclable through existing HDPE streams, fundamentally changing its end-of-life journey.

A Sustainable Future Starts Here: Our planet needs a change. We will unite to achieve it. Join us to be a hero and reduce landfill waste.

Introducing Resin2Film: Innovation for a Circular Economy

Resin2Film is not just another plastic. It's a breakthrough in HDPE technology, engineered for superior durability and 100% recyclability, making sustainable packaging a reality.

The Resin2Film Advantage

- Enhanced Durability: Replaces non-recyclable materials without compromising strength or barrier properties.

- 100% Recyclable: Designed for a circular economy, significantly reducing plastic waste.

- Reduced Carbon Footprint: A more sustainable choice compared to virgin, non-recyclable alternatives.

- Proven & Trusted: Successfully used by major brands in demanding applications.

Why Resin2Film? The Clear Advantage

Transform your packaging strategy with Resin2Film's revolutionary approach. Experience unmatched performance while leading the sustainability revolution in your industry.

Circular Economy Champion

Unlike 98% of retail packaging that ends up in landfills, Resin2Film integrates seamlessly into existing HDPE recycling streams, creating true circular value.

Climate Action Leader

Reduce your packaging carbon footprint by up to 40% compared to traditional multi-layer films while maintaining superior performance standards.

Uncompromised Quality

Achieve OTR rates below 0.23 cm³/m²/24hrs for liquids with enhanced durability that protects products throughout the entire supply chain.

Industry Validated

Trusted by leading brands across food, beverage, and consumer goods industries with proven success in demanding real-world applications.

Ready to Lead the Packaging Revolution?

Join forward-thinking brands who are already benefiting from Resin2Film's superior performance and sustainability.

The Science Behind a Greener Tomorrow

Resin2Film leverages an advanced HDPE formulation, meticulously engineered to provide exceptional strength and full recyclability, a true innovation in sustainable materials.

Advanced HDPE Formulation

Our proprietary Resin2Film technology modifies High-Density Polyethylene at a molecular level. This enhances its structural integrity and barrier properties, allowing it to perform in demanding applications where traditionally, less recyclable or multi-layer materials were the only option. Notably, Resin2Film is the first to offer a high barrier with an OTR (Oxygen Transmission Rate) (cm³/m², 24hrs) of less than 0.23 for liquids, crucial for extending shelf life.

Durability Meets Recyclability

The key innovation lies in achieving superior durability without sacrificing the inherent recyclability of HDPE. Resin2Film can be processed through existing HDPE recycling streams, closing the loop and contributing to a circular economy.

Scientific Touch: Our process ensures polymer chains are optimally aligned for strength, yet remain easily separable during recycling.

Explore Our Applications

Discover how Resin2Film's versatile HDPE solutions can be tailored for various industries, promoting sustainability without compromising performance.

Our Commitment: For a Healthier Planet

Every choice matters. Resin2Film empowers brands to be part of the solution, protecting our marine ecosystems and reducing landfill waste. Together, we can make a difference.

Protecting Marine Life

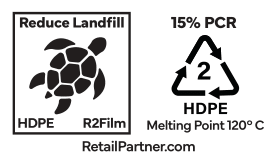

Plastic pollution poses a severe threat to marine animals, including sea turtles. By choosing 100% recyclable Resin2Film, you help reduce the plastic entering our oceans, safeguarding these precious creatures and their habitats.

Look for our R2Film logo to know the product is truly recyclable and you're doing your part in saving our turtles.

Ready to Make the Switch to Sustainable Packaging?

Let's co-create the future of sustainable packaging. Partner with RetailPartner and innovate with Resin2Film to meet your performance needs and environmental goals.